The convergence of machine learning, digital manufacturing, and computational mechanics is transforming the design and fabrication of next-generation materials. My research harnesses data-driven optimization, inverse design, and 4D printing to create adaptive, high-performance structures with applications in robotics, aerospace, biomedical engineering, and sustainable manufacturing. By integrating hierarchical architectures, metamaterials, and bio-inspired design, my work not only enhances energy absorption, mechanical resilience, and intelligent actuation but also redefines the boundaries of programmable materials. Through multimaterial 3D printing, digital twin-assisted modeling, and AI-driven predictive frameworks, my research contributes to the foundation of future smart materials, accelerating breakthroughs in self-healing, self-adaptive, and multifunctional structures that drive technological and societal progress.

Featured Research

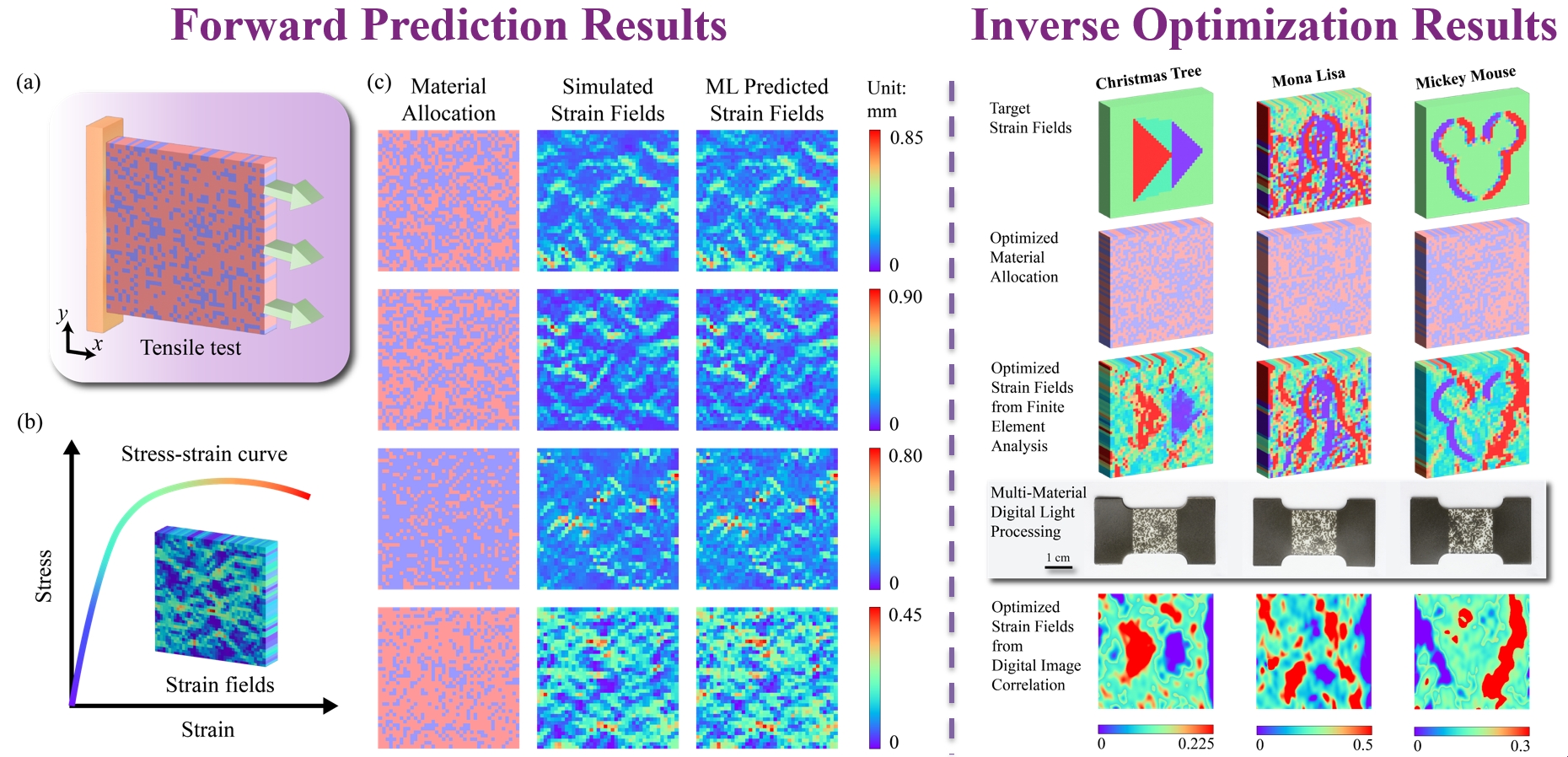

Inverse Design of Strain Fields in Hierarchical Architecture

We develop a machine learning-driven inverse design framework that integrates an RNN-based forward prediction model with an evolutionary algorithm-based optimization method to accurately design strain fields in hierarchical architectures, achieving over 99% prediction accuracy and enabling advanced material applications across multiple engineering domains.

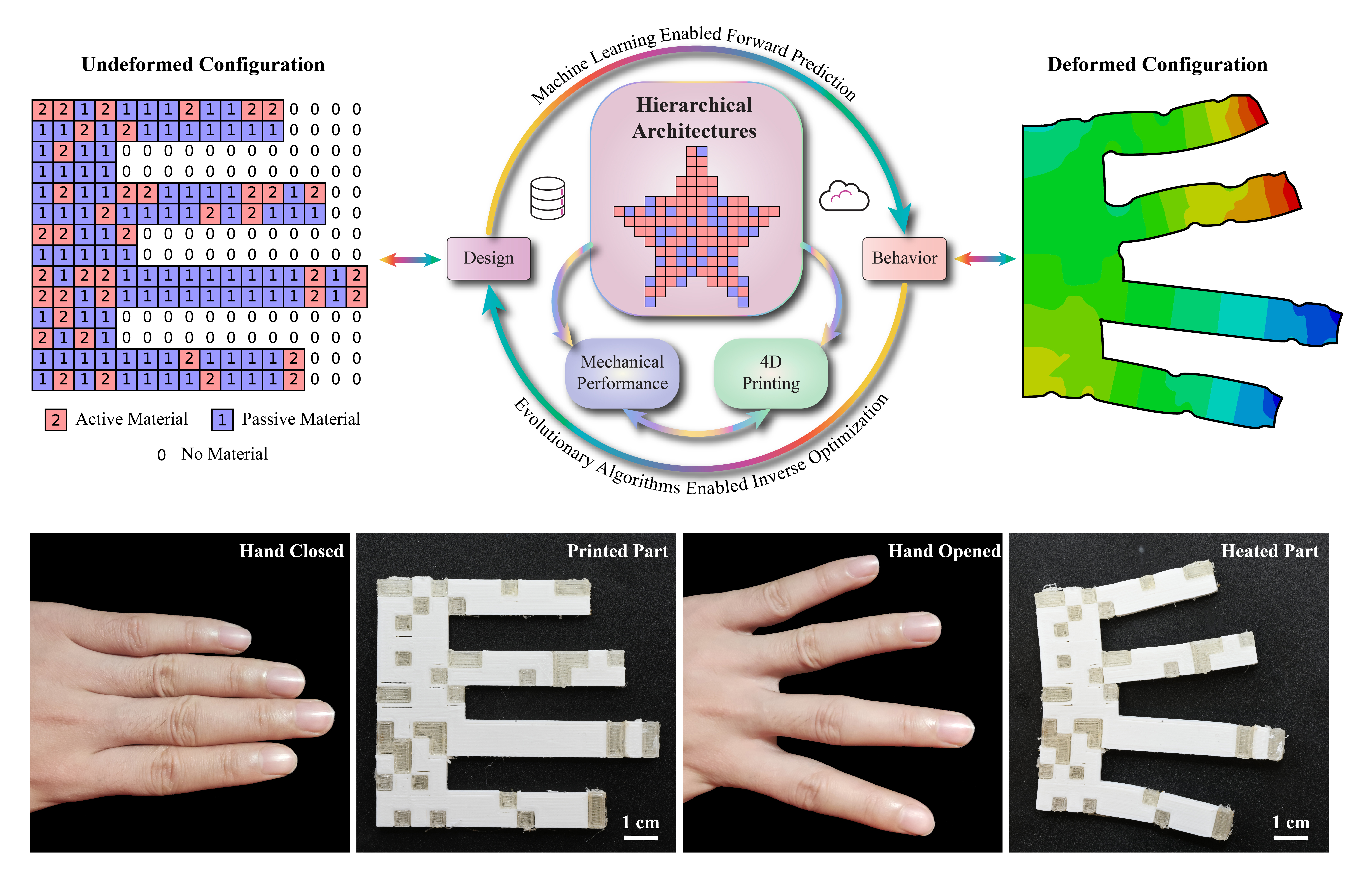

Inverse Design of 4D Printing Effect of Digital Materials

We develop a machine learning-driven framework that enables the forward prediction and inverse design of 4D printed digital materials with arbitrary shapes by integrating ResNet-based prediction and evolutionary algorithm optimization, achieving high accuracy and addressing a key limitation in existing 4D printing design methodologies.

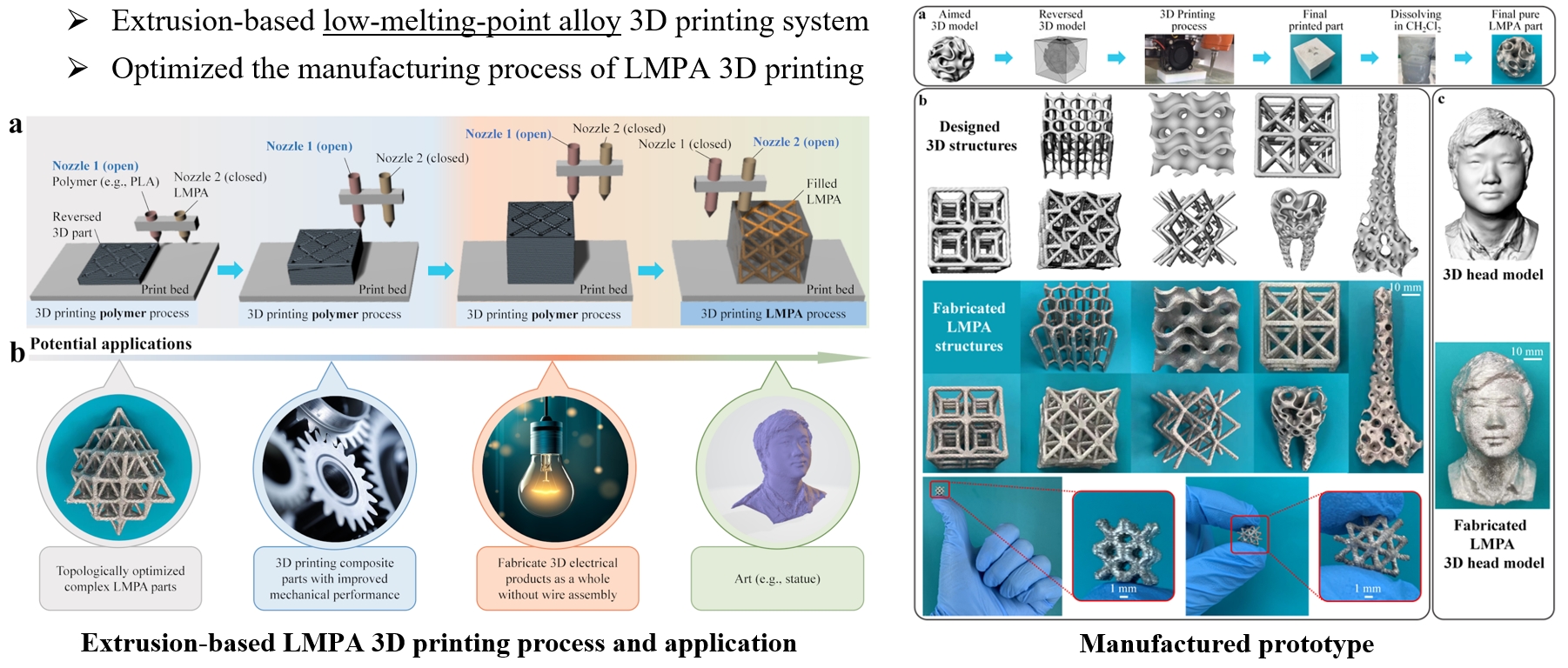

Extrusion-based Additive Manufacturing for Low-melting-point Alloys

We develop a dual-nozzle extrusion additive manufacturing strategy to fabricate complex and multifunctional low-melting-point alloy (LMPA) components, enabling integrated LMPA/polymer structures with enhanced mechanical properties for applications in smart structures, electronics, and energy systems.

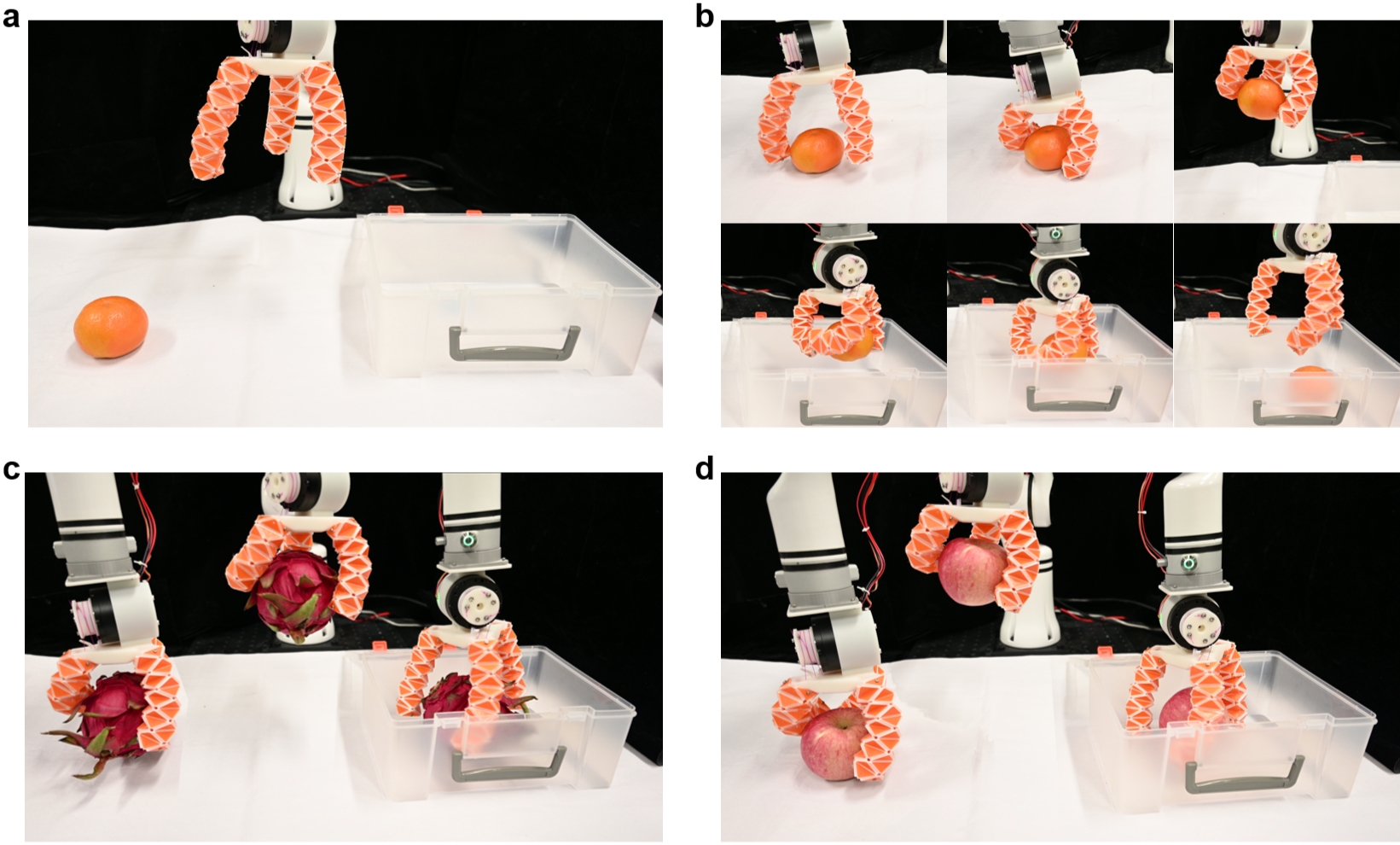

Hard-Soft Coupled Compliant Robot

We develop origami-inspired robotic grippers using hard-soft coupled multimaterial 3D printing, optimizing their kinematic behavior and mechanical functionality through geometric parameter tuning, enabling enhanced flexibility, adaptability, and efficiency in robotic applications.